Test Operations

Test Operations

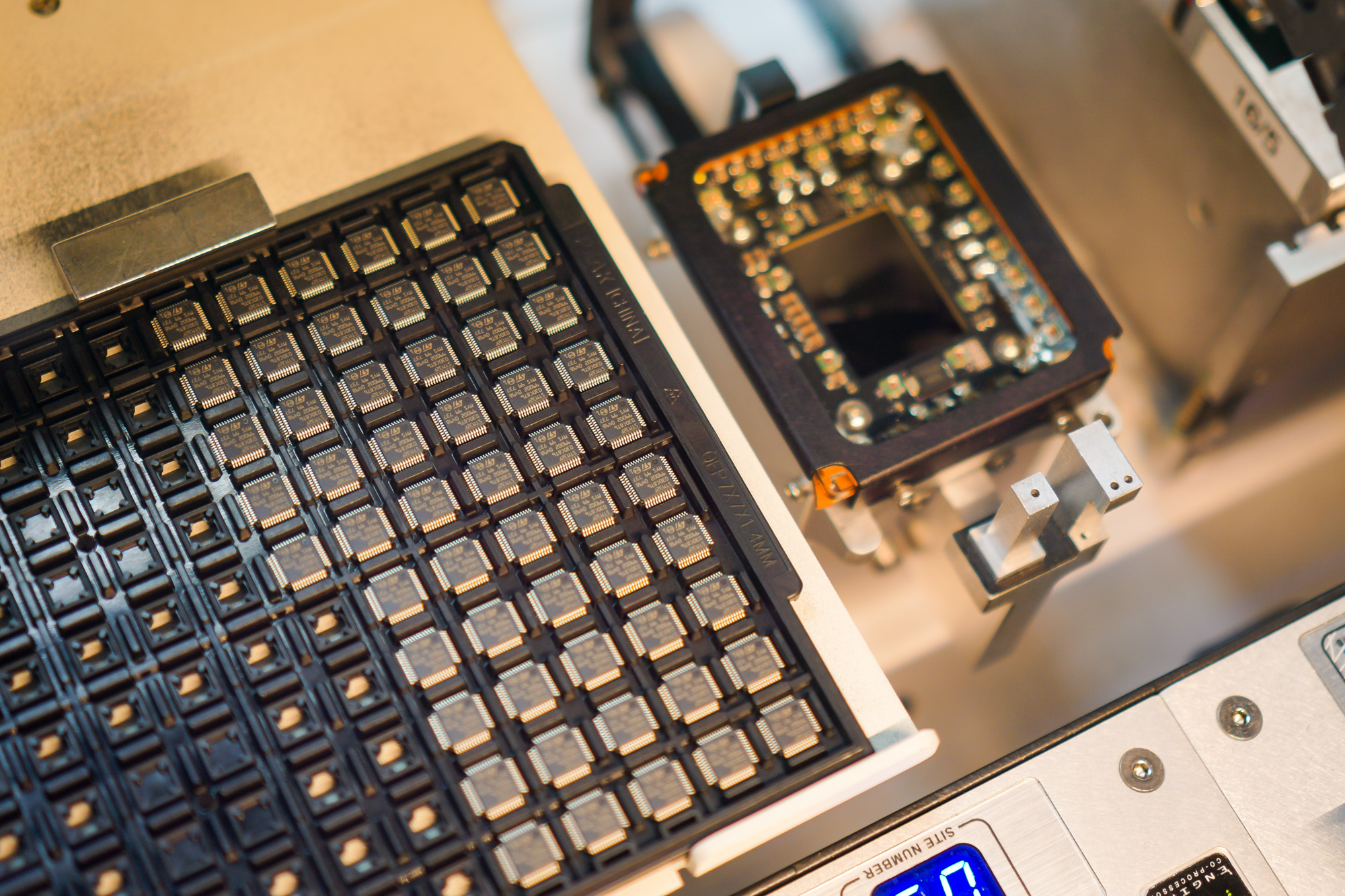

In Nördlingen, we can perform all mechanical, climatic, electrical and optoelectronic tests using state-of-the-art test equipment. We test your chip under grey room conditions up to clean room conditions of class 6 (1000 particles/cubic feet) prior to assembly in the end product.

- Component testing on packages for example QFN, TSSOP, CSP, WLCSP & PLCC, BGA

- Wafer testing from 6 to 12 inch

- AOI of wafer

- End-of-line testing

- Tape & Reel

- Scanning & Straightening

- Burn-in

- Screening

- Series tests at -40 °C up to +125 °C

Test Engineering

Test Engineering

Our experienced engineers develop individual test programs for optimal and efficient testing and adapting of your chips or optoelectronic components such as image sensors, photodiodes or opto ASICs. We support you from the first idea until the delivery of serial parts with following services:

- Development of test concepts

- Development of test software and hardware for analog, digital and RF devices

- Characterisation

- Test program conversion

- Test data evaluation and modification and optimisation of test solutions, especially test time reduction

- Development of electrical tests for qualification and failure analysis

- Testing of power modules (Hi-Voltage)

Device Programming

Device Programming

By using modern handling systems we can customize your components according to your requirements. Programming with fully automatic machines is possible up to 16 devices simultaneously. Laser marking and tape and reel can be carried out in parallel in one work step – a cost-effective solution.